Capacitor Soldering Tip

You've probably seen the trick of bending component pins under the PCB to hold the parts in place during soldering:

This technique is flawed for several reasons, one of which is that it can't be used for components with short leads, such as film capacitors.

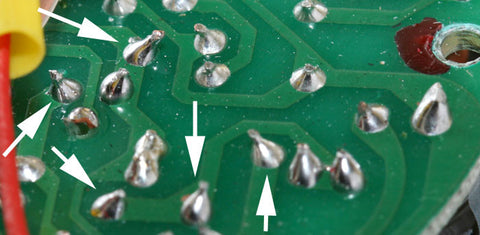

Also, it results in larger (and off-center) solder joints. These joints are harder to desolder, and make it more difficult to clean the board properly. The white arrows indicate especially nasty joints:

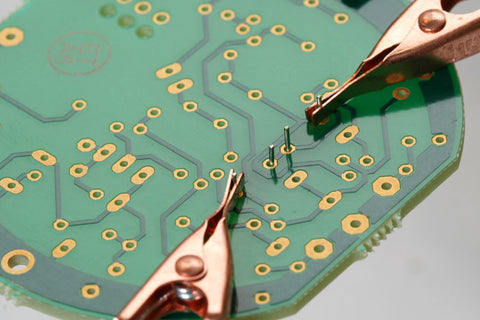

Here's an idea I haven't seen suggested before: use an alligator clip on one of the short pins to hold the part in place. Solder the free pin, remove the clip, then solder the other pin.

Over time, though, I've gotten in the habit of holding components down with low-tack blue masking tape. I can put many components on the board, put a piece of 2-inch wide tape across the top, flip the board, and solder all the leads at once.

The little copper clips pictured above make fantastic heat sinks when soldering sensitive components, such as polystyrene capacitors, although for that application I would mount the clip on the top of the board, between the lead being soldered and the capacitor body.

Have more tips? Send 'em in; we'll publish them here!

More DIY Electronics Tips